Removal of Oil Pump, Replenishment of Engine Oil and Changing of Oil Filter

Removal of Oil Pump

- Remove the drain plug fitted

at the bottom of sump and drain

the oil in a suitable container. Loosen and remove

the sump securing bolt and take out the

sump. Unlock the clamp securing

strainer and remove

bolts of strainer

at the pump inlet. Loosen and remove the pump mounting bolts and take out pump. While removing

oil pump, first remove distributor cover and note the position of

distributor rotor so that, pump may be installed without

disturbing the ignition

timing.

Oil Cooler

- The oil cooler is held with four bolts in the brackets

welded to the frame of the water radiator. Remove the oil cooler

from the vehicle,

wash it with a degreasing solvent, then with hot water, and check it for tightness. The tightness check should be conducted under air pressure

of 4 Kg/Sq. cm in a water

bath. Soldering to leaky

point with soft solder should

eliminate the discovered leak. Minor defects

of radiator frame can be fixed by welding

with subsequent dressing. The number of blocked

tubes should not be exceeding

more than three.

Replenishment of Engine Oil

- For changing the oil, warm up the engine and drain the engine oil by opening the drain plug. After draining the engine oil tighten the drain plug. Pour the light

flushing oil in the engine.

Run the engine

for few minutes

with the flushing oil in the sump, then stop the engine and drain the flushing oil. Never use kerosene

or gasoline for flushing purpose

because of their

low viscosity. Finally

tighten the drain plug and refill with fresh lubricating oil of suitable

specifications as recommended by the manufacturer of the vehicle.

After filling the engine oil, run the engine at medium speed until the lubricating

system is filled with oil. Then stop the engine and wait for oil to settle down. Pull and

wipe out the oil dipstick, insert it all the way back and pull out again. Determine

the oil level by the marks

on the dipstick. The oil level should be at the height of the top

mark of the dipstick.

Changing of Oil Filter

- Loosen the oil filter with the help of filter wrench. Discard old filter and replace with new one. Before fitting new filter lubricate oil seal of new filter

with the layer of

lubricating oil and fill the filter with lubricating oil.

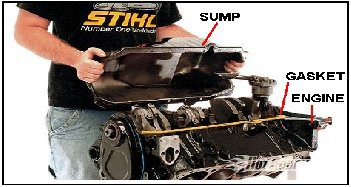

Removal & Installation of Oil Sump

One of the most important fluids in an engine. It lubricates and cools the moving parts of the engine. The oil change cycle for an engine is a function of driving conditions and should be changed as scheduled by the manufacturer of the vehicle. It is important to monitor oil properties to gauge the necessity of a decrease in the oil change interval.

Removal of Oil Sump. Drain out the engine oil. Unscrew bolts of clutch housing cover and take it off. Unscrew oil sump bolts, remove sump and gasket. If gasket fails to come off easily, detach it with a screwdriver or knife.

|

| Engine Oil Drain |

|

| Oil Sump Bolt |

Installation of Oil Sump. Before installing the oil sump, make sure that there are no foreign articles inside the engine. Coat the lower portion of the cylinder liberally with oil and lubricate the piston, pins, main and big end bearings on the outside.

|

| Sump Removed Engine |

Put the gasket on the joint between the cylinder block and the oil sump. Blow the sump with compressed air and install it on the cylinder block. Screw in the bolts washers by hand and tighten them with a socket wrench.

Faults in Lubrication System (General)

Low Oil Pressure.

|

Causes

|

Remedy

|

|

Diluted or thin oil

|

Change oil

|

|

Oil pump strainer clogged

|

Clean strainer

|

|

Worn pump gear

|

Overhaul pump

|

|

Main and big end bearings badly worn

|

Replace bearings

|

|

Weak relief valve spring

|

Change the spring

|

|

Leak in the system

|

Trace and rectify

|

|

Engine over heating

|

Trace and rectify

|

|

Pressure gauge u/s

|

Replace

|

Excessive Oil Consumption

|

Causes

|

Remedy

|

|

External leaks

|

Trace and rectify

|

|

Burning oil in the combustion chamber

|

Check valve

stem clearance, Check piston rings,

change if worn out

|

|

Oil level too high

|

Maintain oil at correct

level

|

|

Poor quality

or improper viscosity of lubricating oil

|

Use correct grade of lubricating oil

|

High Oil Pressure

|

Causes

|

Remedy

|

|

Oil too thick (wrong

grade)

|

Fill correct grade

|

|

Chocked passage

of relief valve

|

Rectify

|

|

Relief valve pressure set too high

|

Set Correctly

|

|

Pressure gauge

Faulty

|

Replace with new one

|

Crankcase Ventilation

It is quite

possible that the product of combustion containing

nitrogen, water and carbon dioxide

may leak through

piston rings into the crankcase.

The crankcase ventilation is used in all automotive engines.

It consists of passing through

the crankcase a constant stream

of air which picks up and carries

away most of the fuel vapor and water vapor before they can condense out and dilute the lubricating oil. Air is drawn into the crankcase

through the breather cap and is discharged through an outlet tube at the side of the engine. There are two type of crankcase ventilation used in automobile engines.

- Open Crankcase Ventilation. In open crankcase ventilation, the crankcase vapors are exhausted into atmosphere.

|

| Open Crankcase Ventilation |

- Positive Crankcase Ventilation. In positive crankcase ventilation, the crankcase vapors are returned to the engine through the intake manifold, instead of being exhausted into atmosphere. The crankcase out let tube is connected to the intake manifold just beneath the carburetor, so that the vapor are drawn into the intake manifold and utilized into the cylinder during the combustion.

|

| Positive Crankcase Ventilation |

Subscribe to:

Comments (Atom)